What we supply?

Q1: What is plastic Injection molding?

-

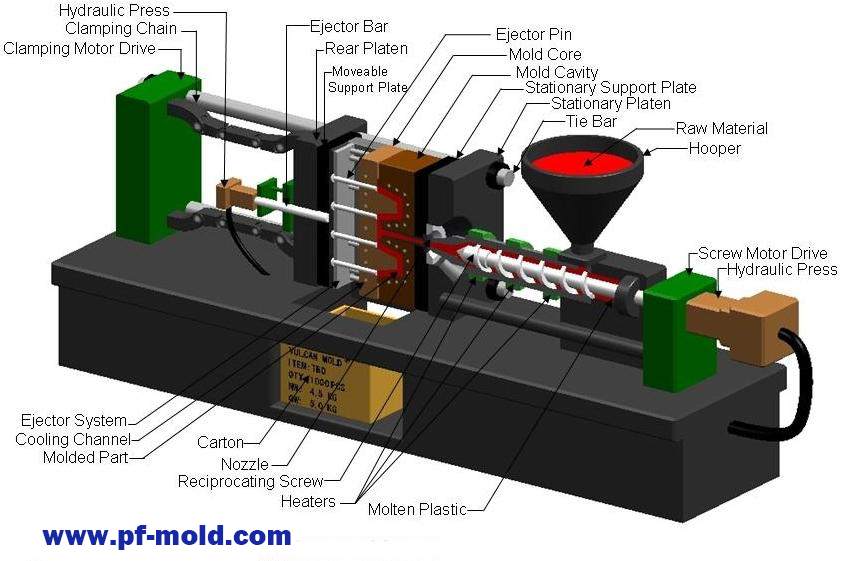

A1: Molding plastic injection process starts with small pellets compounded to meet certain physical properties.

-

These pellets are then dried and fed into a hopper, which allows them contiously dried and fed into the throat of the machine.

Plastic Injection Moulding Process Description (Photo)

The machine then melts the plastic in a heated barrel, and injects it under high pressure out of the barreland into your injection mold cavity. The injected plastic quickly fills the cavity, and it is then allowed to cool while the machine fills its barrel for the next cycle. As the plastic cools, it changes back to a solid. After a set amount of time, the mold opens, exposing the part, and hydraulic ejector pins push the part out of the cavity.We welcome to hvae a communication about the injection molding machines.

-

Q2: What kind of plastic injection molding machines does your comapny have?

-

A2: Our factory has equipped with more than forty sets of plastic injection molding machines, which tonnage are from 50T to 600T. And we have imported several sets of new injection moulding machines from South Korea which tonnage are about 1000T. So, our various injection molding machines can produce the higher quality products for you at the lower cost.

-

Q3: Does you company offer double-coloured injection molding service?

-

A3: Yeah. Our factory have equiped with two sets of double coloured injection molding machines. And we also can design and make double colored plastic injection molds. As we have more than five years of experience of designing, making double colored plastic molds and producing double colored molded plastic parts, so we have the ability to supply the high quality service at low cost for you.

Q4: How many workers are your company usually responsible for operation of injection molding machines£¿

-

A4: Usually, we arrange two workers to operate one injection molding machine. They are not only reponsible for the producing but also the maintenance of machine. They usually make a maintenance every week. In addition, we also arrange the specific workers to test, check and solve other technical problems. Just like this, we can provide the best products for you at the lower cost.

Print

Print